Location: Home > Applications > Industrial Devices

Industrial Processing

Solid state relays are widely used in various types of industrial processing equipment, such as: laser cutting machine, water jet cutting machine, casting machine, injection molding machine, glass edging machine, mobile dryer, paint dispenser, blender, etc.

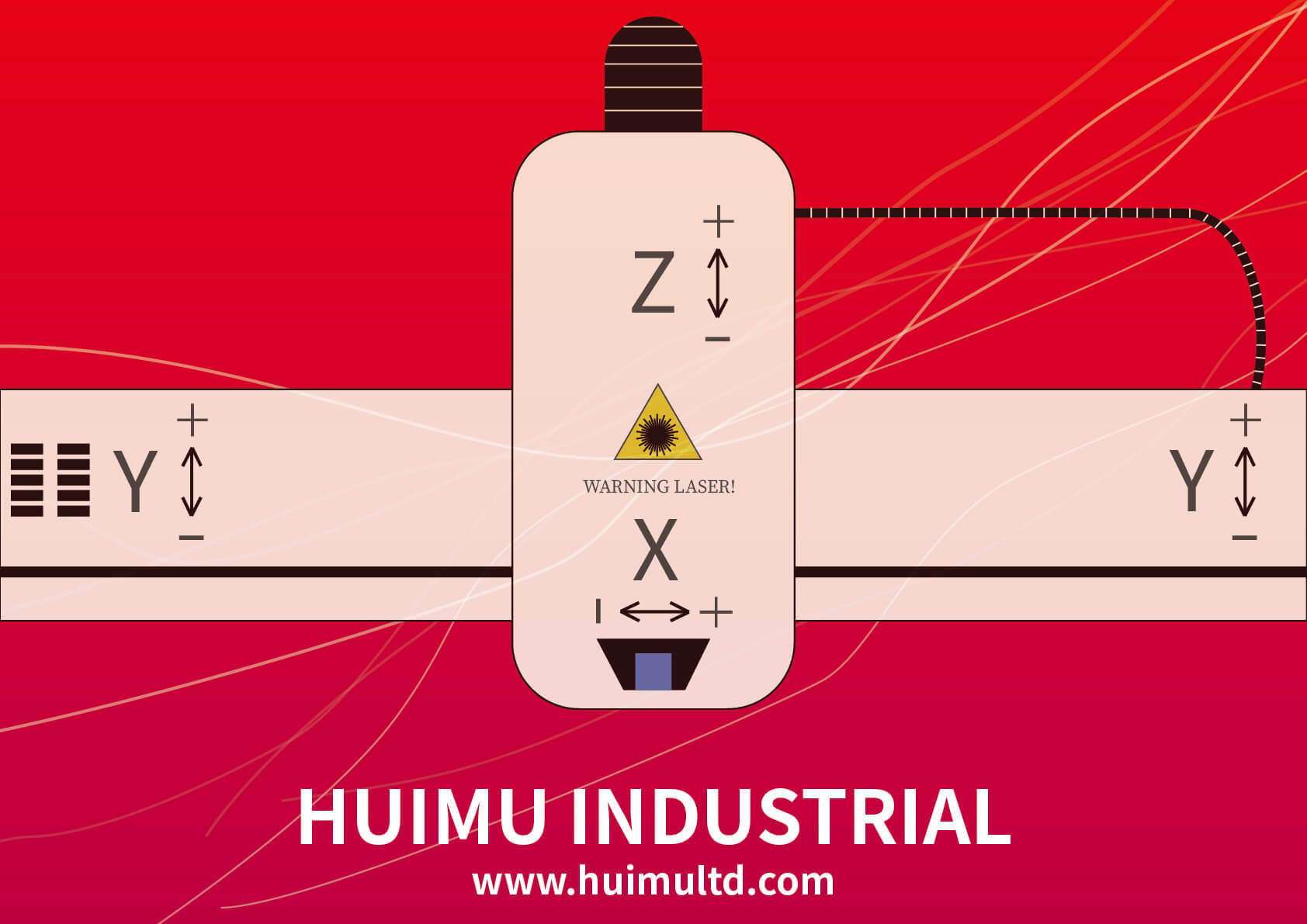

Laser Cutting Machine

Introduction:

Introduction:

Laser cutting machine (or laser cutter) uses high energy laser as cutting tool. It is composed of laser generator, cutting head, operation table, chiller, power supply, air cooling dryer, filter, slag discharger, exhaust dust collector, etc. Among them, the numerical control system controls the machine tool to realize the X, Y, Z axis movement, and also controls the output power of the laser; the stabilized power supply is connected between the laser, CNC machine tool and the power supply system to ensure the stability of the power system.

Working process:

1. The laser generator is the light source of the laser, and the laser is directed to the desired direction by an external light path (a kind of refractive launch mirror).

2. The laser cuts the items on the operation table through the cutting head (mainly including the cavity, the focusing lens holder, the focusing lens, the capacitive sensor and the auxiliary gas nozzle, etc.).

3. The chiller cools the laser generator to prevent it from burning down due to overheating.

4. The air compressor supplies the compressed air from the air storage tank to the air cooling dryer and filter to supply clean dry air for the laser generator and the beam path, and also to maintain the normal operation of the path and the reflector.

5. The ventilation dust collector extracts the smoke and dust generated during processing, and performs filtering treatment to make the exhaust gas emission comply with environmental protection standards.

6. The corner residual materials and waste materials generated during processing are finally discharged through the slag discharger.

The role of solid state relays:

1. Adjust the laser output power and the movement direction of the machine tool.

2. Control the working state of air compressor and dust collector.Water Jet Cutting Machine

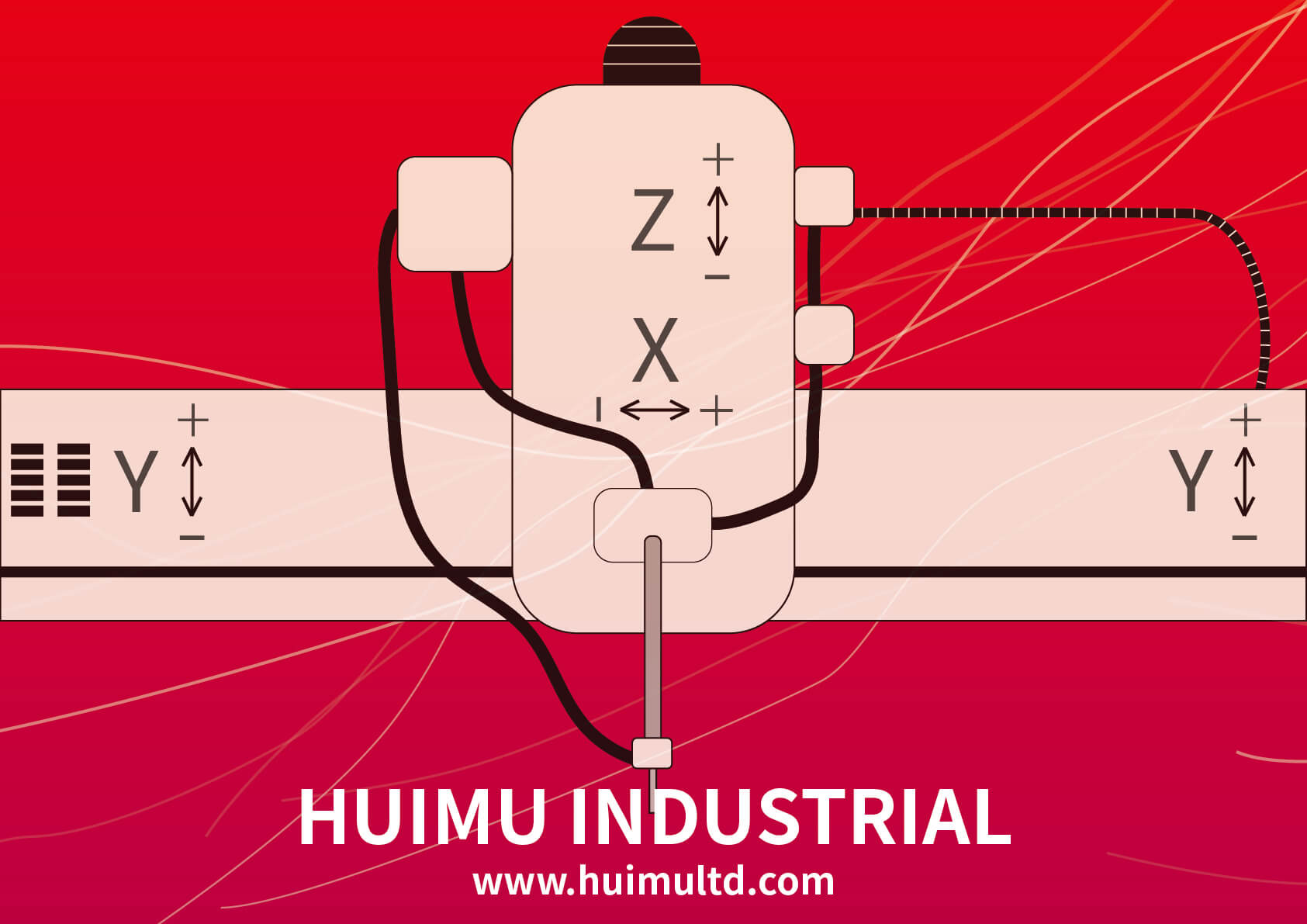

Introduction:

Introduction:

The water jet cutting machine, or water jet cutter, is a device that uses a high-pressure water jet as a cutting tool. The water jet cutting machine is composed of ultra-high pressure water pump, pressure accumulator, water jet cutting head, cutting table (X, Y, Z axis), and numerical control system. The waterjet can perform curvilinear cutting on any material, and at the same time, the high-pressure water flow in the cutting process will take away the heat and waste generated during the cutting processing. Due to its low cost of use and maintenance, safety and environmental protection, and high efficiency, it is widely used in various types of machining.

Working process:

1. The ultra-high pressure water pump pressurizes ordinary tap water to 400MPa and flows into the accumulator to obtain stable high-pressure water.

2. High-pressure water passes through a waterjet cutting head (a nozzle with a diameter of about 0.1-0.4mm), generating a high-pressure water jet of up to 1km/s.

3. The numerical control system controls the movement of the cutting table to cut the items on the machine.

4. The waste material generated during the cutting process will be discharged through the drain pipe along with the water flow.

The role of solid state relays:

1. Control the working state of the high-pressure water pump.

2. Adjust the movement direction of the cutting table.Injection Molding Machine

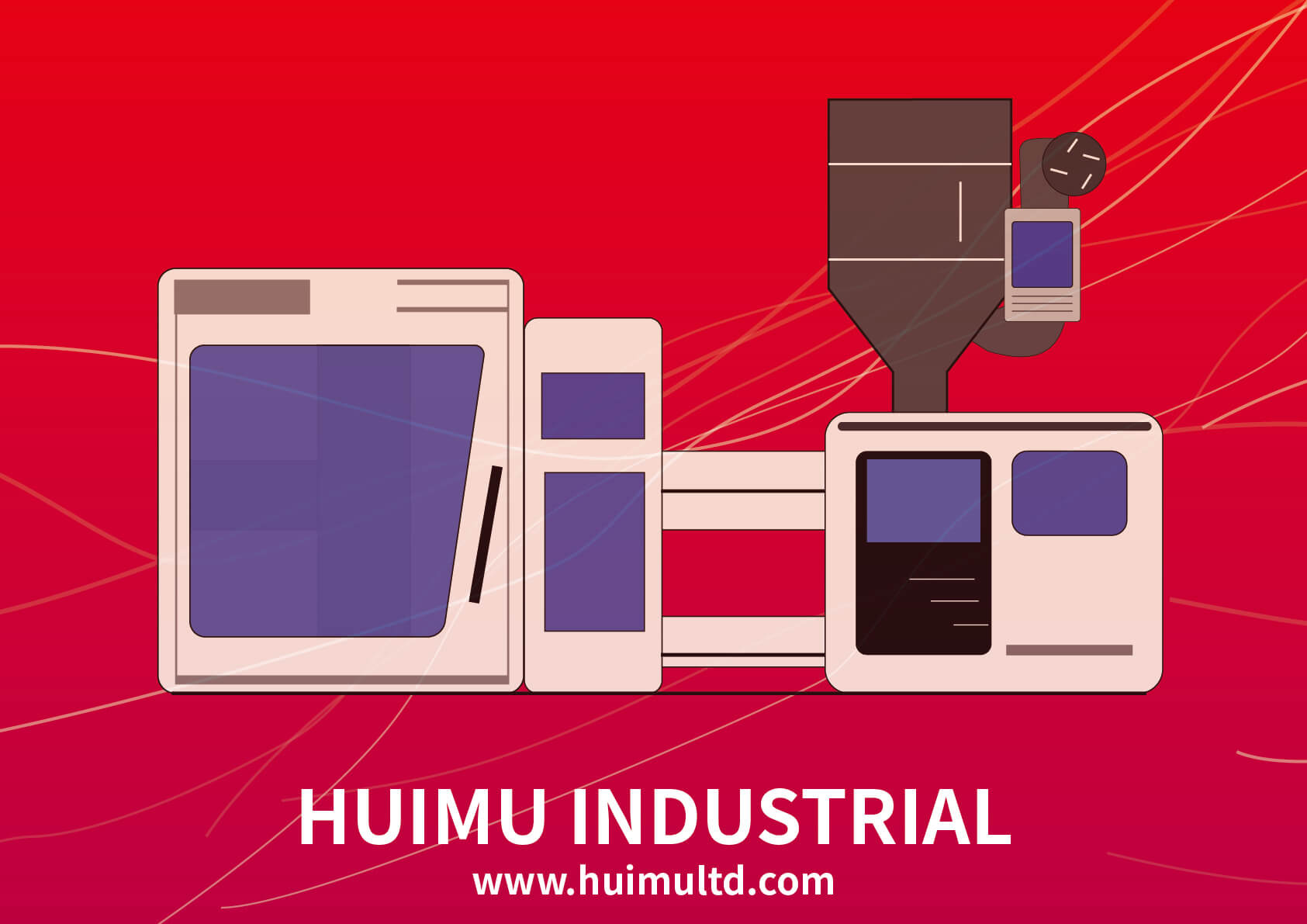

Introduction:

Introduction:

The injection molding machine can be divided into vertical injection molding machine and horizontal injection molding machine. It is composed of an injection system, a mold clamping system, a hydraulic transmission system, an electrical control system, a heating and cooling system, etc. The injection molding machine can press thermoplastic or thermosetting plastic into the mold, and forms plastic products of various shapes after the plastic cools.

Working process:

1. The heating system heats the plastic raw material to liquid state, and injects the liquid plastic into the mold through the injection system.

2. After the function of the cooling system, the take-out device takes the molded plastic products out of the injection molding machine.

The role of solid state relays:

1. Control the working status of hydraulic transmission system, injection system, mold clamping system.

2. Adjust the temperature of the heating system and cooling system.Glass Edge Grinder

Introduction:

Introduction:

The glass edge grinder (or glass edging machine, lens edger), is generally composed of grinding head motor, grinding wheel, glass support frame, and floor water tank. The control electronic circuit can control the edging machine to make proper mechanical movement according to the material and size of the glass to make the glass meet the requirements.

Working process:

1. Input the glass material, size and other information into the computer system, and place the glass on the glass support frame.

2. The grinding wheel polishes the glass.

3. The rail system transports the cleaned glass out.

The role of solid state relays:

1. Control the working state of the motor and guide rail system.Mobile Dryer

Introduction:

Introduction:

The mobile dryer is a kind of dryer, which is composed of a frame, a heating panel, and a temperature adjustment system. Through wheels underneath, the mobile desiccant can be moved to the designated position as needed, and by heating the surface of the object, its internal moisture is vaporized and discharged.

Working process:

1. Adjust the heating panel through the temperature adjustment system.

2. The heating unit on the heating panel generates heat when energized.

The role of solid state relays:

1. Control the working state of the heating panel.Paint Dispenser

Introduction:

Introduction:

The paint dispenser (or latex paint tinting machine) can generate colorful latex paint by mixing different colors. It is composed of color matching system, oil pump, color paste, paint bucket, etc.

Working process:

1. Enter the specified color to the computer, and the color matching system will open the corresponding oil pump.

2. The corresponding latex paint flows into the paint bucket one by one through the color paste bucket.

The role of solid state relays:

1. Control the working state of the oil pump.Blender

Introduction:

Introduction:

The blender (or mixer) is a device that forces liquid and gas to convection and mix evenly by physical means. It is composed of CNC system, mixing system, etc.

Working process:

1. Pour liquid, gas, etc. into the mixing vessel.

2. Adjust the working power and speed of the stirring motor through the CNC system.

The role of solid state relays:

1. Control the working state of the stirring motor.Recommended Solid State Relay

Get in touch with us now!

Please take a minute or two to complete this simple form to get reply in 24 hours, thank you!

*Please check the trash box of your mailbox, if you do not receive our email.